Developed by the Institute of Engineering Thermophysics, Chinese Academy of Sciences (CAS), CGAS Circulating Fluidized Bed Coal Gasification is a high-efficiency, clean coal conversion solution with over a decade of R&D. Its industrialization was supported under the CAS "Hongguang Special Project" for key technology transfer.

As the industrialization platform, CAS Hefei Coal Gasification Technology Co., Ltd. provides coal gasification systems leveraging CGAS technology. Key breakthroughs include:

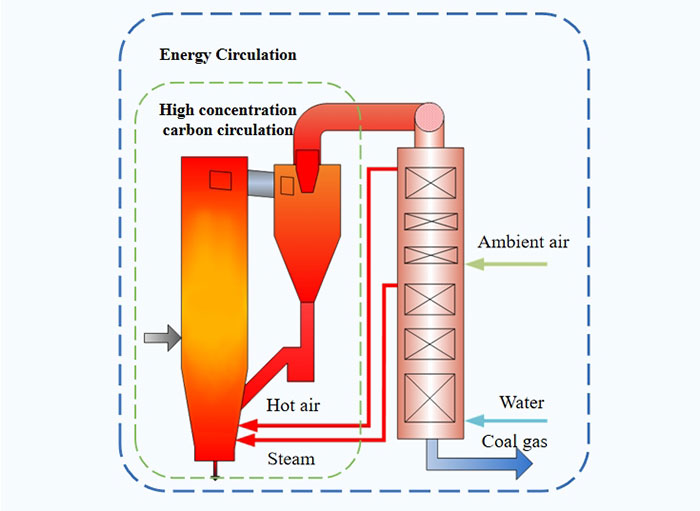

· High carbon/energy circulation via CFB-enhanced loops

· Efficient, low-cost conversion under mild conditions

· Flexible gasification agents:

☆Air/Pure O?/O?-enriched air → Industrial fuel gas

☆ O?-enriched/pure O? → Syngas/H?