As of 9:00 AM on December 5, 2023, Unit 3 gasifier of the Xiamen Xiangsheng Circulating Fluidized Bed Coal Gasification Project, constructed by ZHGAS achieved 1,000 days of continuous and stable single-furnace operation, setting a new record for continuous operation of a circulating fluidized bed gasifier using high-moisture lignite as raw material. Furthermore, Units 1 and 4 gasifiers have both exceeded 700 days of continuous operation, and Unit 2 is approaching 600 days, demonstrating the overall project's long-term safe and stable operation.

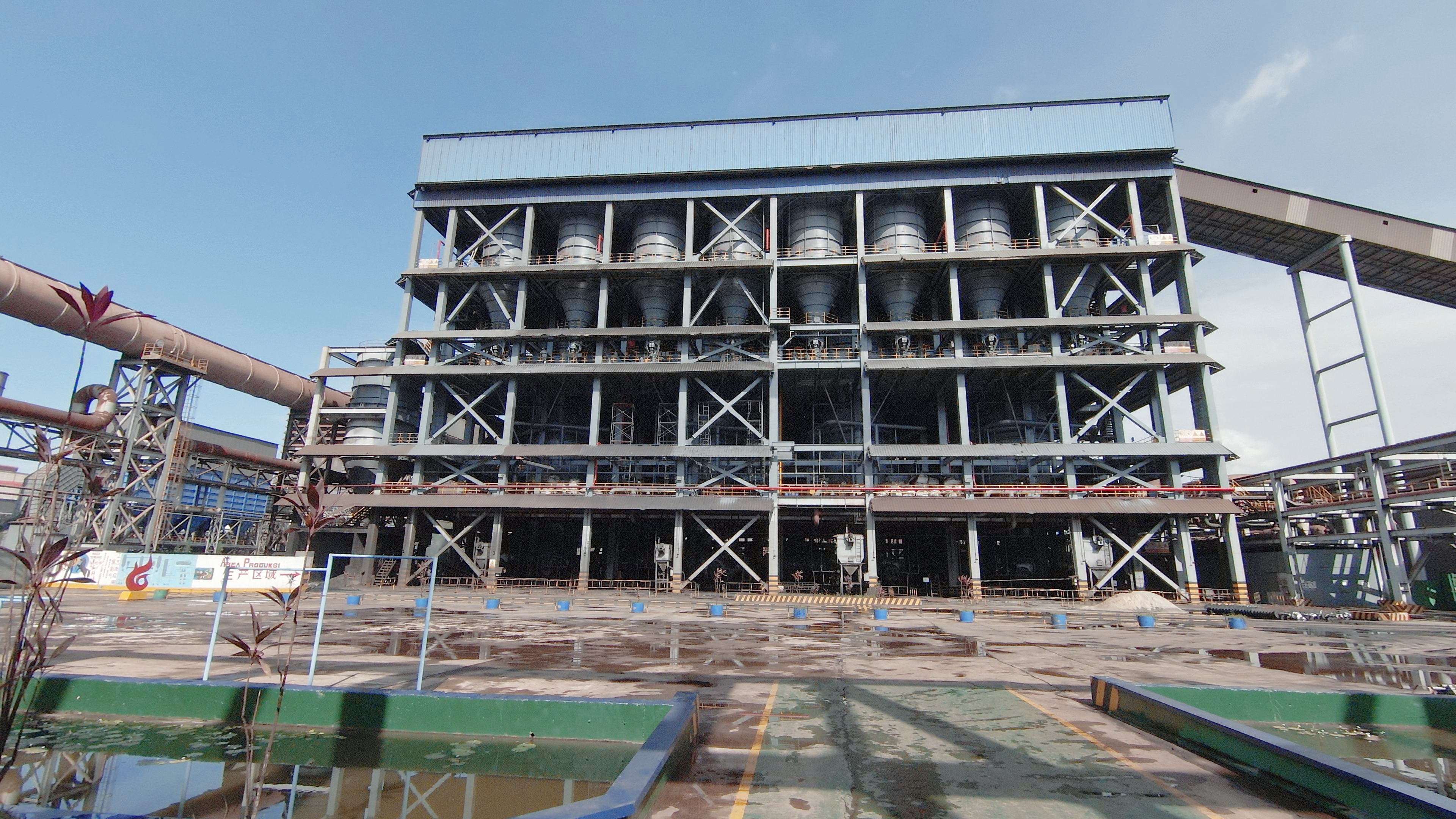

Located in Konawe county, Kendari City, Southeast Sulawesi, Indonesia, the project is designed to construct a supporting coal gasification plant for a local integrated stainless steel smelter with an annual production capacity of 2.5 million tons. The industrial gas produced will serve as fuel for the rotary kilns in the nickel-iron production line. Addressing the characteristics of local lignite, such as high moisture content (up to 40%), poor mechanical strength, and low thermal stability, ZHGAS utilized circulating fluidized bed coal gasification technology to build four pulverized coal gasifiers for the owner, each with a capacity of 80,000 Nm3/h. This technology can process raw coal with high moisture content, allowing it to enter the gasifier without prior drying, thereby achieving clean and efficient utilization of the local low-grade coal.

The project has been operating smoothly with excellent performance indicators since its official commissioning in 2021.Previously, the owner utilized a pulverized coal firing process to provide heat for the rotary kiln. This method had certain requirements for raw coal quality, leading to higher raw material costs. Moreover, as pulverized coal was directly injected into the kiln for combustion, the noise and dust generated during the pulverization and injection processes severely polluted the local environment and endangered the health of operating personnel. The replacement of pulverized coal with natural gas has significantly reduced raw material costs, simultaneously resolved the pollution problem, greatly freed up labor at the refinery, enhanced the plant's automation level, and ensured the quality of the final product. The operational results have been highly praised by the owner.