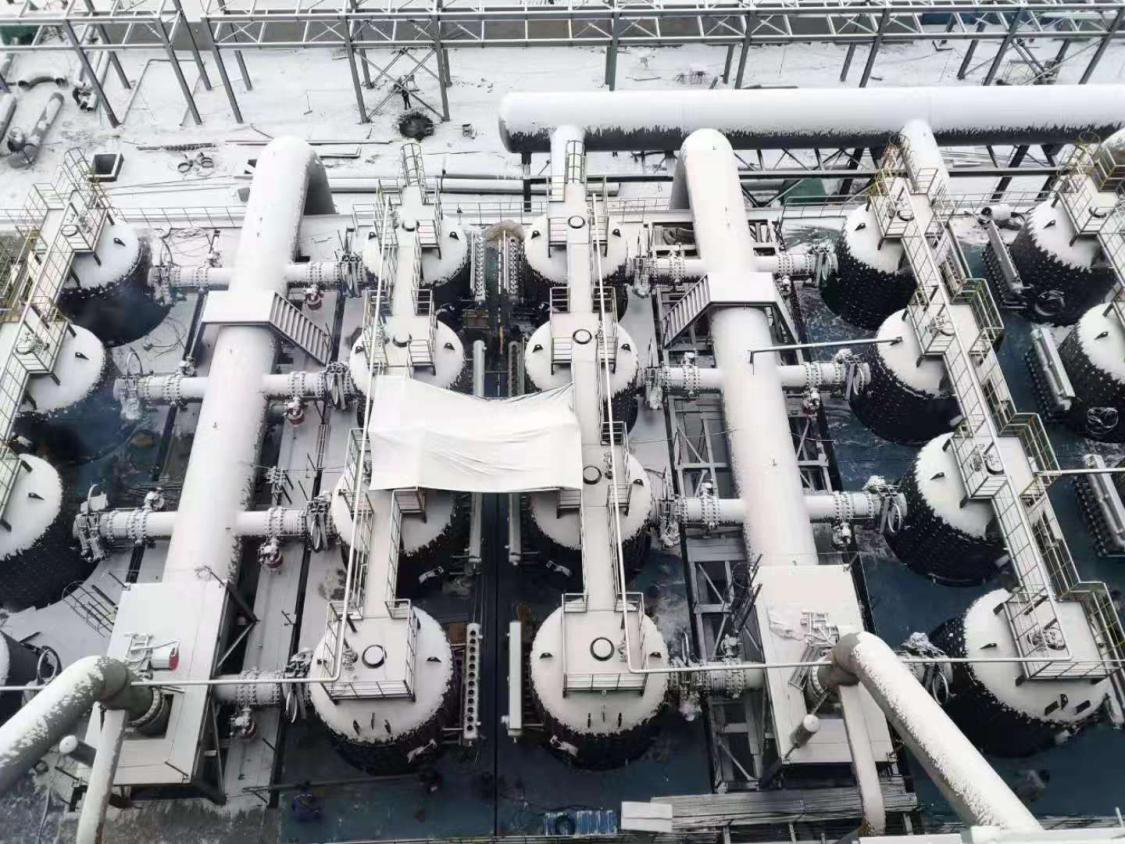

As winter set in, temperatures in Xinjiang's Zhundong Wucaiwan area continued to drop, with daily highs often hovering around minus ten degrees Celsius. However, at the construction site of ZHGAS.'s Xinjiang Yihua Coal Gasification Plant Project, a group of dedicated engineers and construction workers remain, battling the snow and severe cold. While prioritizing "safety and quality," they are racing against time to ensure the project progresses on schedule.

The Xinjiang Yihua Coal Gasification Plant Project is an EPC (Engineering, Procurement, and Construction) general contracting project that includes civil works. Its construction difficulty and scale are self-evident, influenced by factors such as the geographical location, climate conditions, and time difference of the construction site.

As early as early November this year, the Xinjiang Yihua project department began making thorough preparations for winter construction. To ensure the successful completion of the annual plan, the project department actively deployed resources, convened a special meeting on winter construction, and formulated a winter construction plan and safety management measures based on the characteristics of climate change in the Xinjiang region and the actual site conditions. They refined winter construction measures, made detailed arrangements for winter construction safety, quality, and progress, and organized unified pre-job technical and safety training sessions on winter construction for all subcontracting units by project personnel.

For key and challenging projects, the project department ensured proper planning, inspection, and implementation. Following the principle of "inspecting while rectifying," issues discovered were promptly raised, and clear rectification requirements were specified, with a system for tracking and closing out these issues within the hidden danger investigation system. At the same time, problems were thoroughly analyzed, weak links in quality and safety were comprehensively strengthened, and a long-term mechanism for quality and safety management was gradually established.

Furthermore, to motivate construction personnel, the Xinjiang Yihua project department, in conjunction with the owner and subcontractors, signed responsibility agreements, ensuring clear division of labor and well-defined objectives. Corresponding assessment and reward/penalty mechanisms were formulated based on different project milestones and duly implemented.

Under the strategic planning and coordination of the project department, on December 20th, the secondary cooler gas outlet pipeline was successfully connected to the external pipe rack's main gas pipeline. The entire process piping system at the Xinjiang Yihua Project site is complete and meets the conditions for pressure testing. As of now, on-site mechanical and electrical installation is nearing completion, and closing-out work for all disciplines is proceeding in an orderly manner. The entire project is entering the countdown to commissioning.

Xinjiang Yihua, strategically located in Wucaiwan, Zhundong, Jimsar County, Xinjiang, holds the distinction of being the first major enterprise to establish operations in the Zhundong region. Currently, it boasts a production capacity of 400,000 tons per annum of synthetic ammonia and 600,000 tons per annum of urea. Previously, the company utilized fixed-bed gasifiers, which necessitated high-quality raw coal and incurred significant costs. To address this, ZHGAS's research and development team, through thorough investigation and with a commitment to fully leveraging local coal resources, designed and adopted Circulating Fluidized Bed (CFB) coal gasification technology for a new pulverized coal gasification plant. This innovative approach specifically accounts for the local coal's unique characteristics, such as high moisture content, low melting point, and elevated levels of calcium, sodium, and potassium. The new facility features three CFB gasifiers, each with a single-unit capacity of 60,000 Nm3/h, and upon completion, it will provide essential feedstock gas for Xinjiang Yihua's synthetic ammonia production system.