ZHGAS: Leading Innovation in CGAS Circulating Fluidized Bed Coal Gasification Technology, Empowering Efficient Conversion of Clean Energy

As the "dual-carbon" goals accelerate the energy transition, industries such as coal chemical engineering, metallurgy, and building materials are facing critical choices concerning survival and upgrading: How to balance cost reduction and efficiency improvement while adhering to environmental protection thresholds? How to revitalize coal, a traditional energy source, with new vitality through clean and efficient utilization?

ZHGAS, as the industrialization platform for the Chinese Academy of Sciences' circulating fluidized bed coal gasification technology, is leveraging its "national team" research heritage and globally validated engineering track record to provide the industry with end-to-end solutions covering technological innovation, engineering design, and project implementation. Here, "advanced technology" is not a slogan but tangible benefits that cut annual costs by millions; "engineering strength" is not a label but an industry record of 1,545 consecutive stable operation days. Choosing us means aligning with a pioneer in energy transition, ensuring every investment translates into visible competitiveness.

Strong Endorsement from the Chinese Academy of Sciences, Solid Research Foundations Build Industry Barriers

ZHGAS's core technology, the CGAS circulating fluidized bed coal gasification technology, originates from the Institute of Engineering Thermophysics, Chinese Academy of Sciences—the largest R&D institution for circulating fluidized bed technology in China. The institute holds over 130 related patents and boasts the highest technical market share in the country. Its technical strength and research resources strongly support ZHGAS in the industrial promotion and application of CGAS technology. Meanwhile, relying on the institute's research platform, ZHGAS continuously advances technological upgrades and product innovation to provide customers with better industrial solutions and services.

Over the past decade, ZHGAS and the institute have jointly built a complete R&D system encompassing "applied basic research - lab-scale testing - pilot-scale testing", successfully developing a full range of technologies with capacities from 10,000 to 90,000 Nm3/h, adaptable to various gasification methods such as air, oxygen-enriched, and pure oxygen. From high-alkali coal at Xinjiang Yihua, low-quality anthracite at Guizhou Hongsheng to high-moisture lignite at Indonesia Xiangsheng, the CGAS technology has fully demonstrated its universality for "three-high" low-quality coal and low-reactivity coal in industrial applications across over ten industries including synthetic ammonia, alumina, ferronickel, lithium batteries, and glass. This truly transforms the "research platform" into customers' technical confidence.

CGAS Technology Reduces Costs and Enhances Efficiency, Reshaping Industry Benchmarks for Benefits

Compared with traditional gasification technologies, CGAS technology has reshaped industry perceptions with tangible benefits: A single 80,000 Nm3/h gasifier can help customers reduce annual costs by over 15 million yuan, making it the "preferred solution" for quality improvement and cost reduction. Its core advantages directly address industry pain points:

High efficiency and low consumption: Unique equal-diameter upper and lower gasifier + large cyclone separator design enables full circulation of high-temperature materials, improving both carbon conversion rate and gas production efficiency while significantly reducing coal consumption.

Flexibility and stability: 30-minute quick startup (in hot standby state) and high automation ensure production continuity.

Versatility with coal types: Adaptable to lignite, anthracite, "three-high" low-quality coal, and pulverized coal, allowing customers to flexibly select coal to reduce costs.

Optimal energy efficiency: System energy efficiency and carbon conversion rate lead the industry through high-temperature preheating, waste heat recovery, and other technologies.

Zero waste discharge: No tar, phenols, or wastewater; solid slag discharge + dry ash removal ensures compliance with environmental standards.

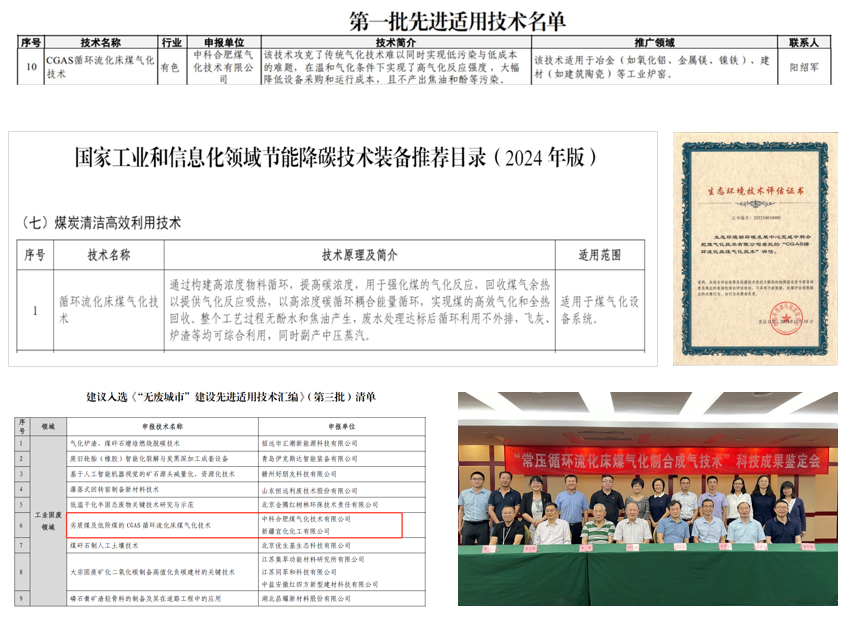

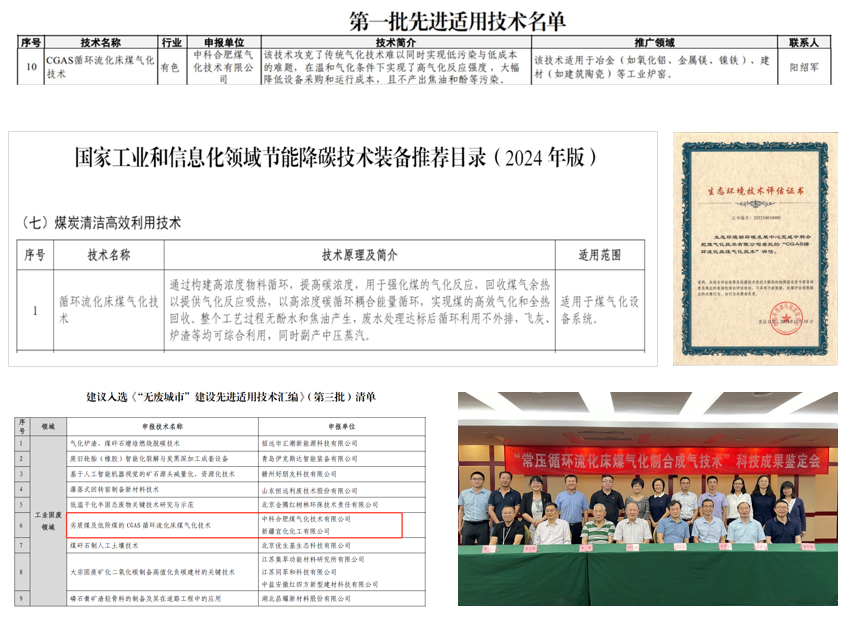

In recent years, CGAS technology has been included in multiple authoritative lists, such as the National Energy-Saving and Carbon-Reducing Technology and Equipment Recommendation Catalog for the Industrial and Information Technology Sector, the Ministry of Industry and Information Technology's first batch of Advanced and Applicable Technologies Catalog, the National Eco-Environmental Science and Technology Achievement Transformation Comprehensive Service Platform, the "Advanced and Applicable Technologies for 'Zero-Waste City' Construction" (Ministry of Ecology and Environment), and Anhui Province's Energy-Saving and Environmental Protection "Five-Hundred" Advanced Technologies. It has passed the assessment by the Environmental Development Center of the Ministry of Ecology and Environment, been recognized as Anhui Province's "First Set" Major Technical Equipment, and undergone technical appraisal by the China Petroleum and Chemical Industry Federation. As a clean production technology recognized and supported by the state, it highly aligns with China's green development trend for fossil energy.

In-depth Integration of Industry, Academia, and Research, Building a Technological Moat

Talent is the core guarantee for technology implementation. The core R&D personnel of ZHGAS's R&D team all come from the Circulating Fluidized Bed Laboratory of the Institute of Engineering Thermophysics, Chinese Academy of Sciences, with over ten years of experience in R&D, design, construction, and operation of circulating fluidized bed gasification technology in lab-scale, pilot-scale, and industrial applications. They have gone through the entire process of R&D innovation and industrial application, possessing excellent technical R&D and engineering transformation capabilities. Designers mostly come from well-known domestic design institutes, with extensive experience in project consulting, planning, and design. The commissioning and operation team provides "full-life-cycle services"—from operation training to dynamic technical upgrades—to ensure long-term stable operation of customers' projects.

Over 60 Global Projects Validate, Practical Achievements Build Reputation

Leveraging the mature technical accumulation of the Chinese Academy of Sciences, which has been applied in engineering since 2009, the company has built over 60 sets of large-scale gasification units in more than 20 projects worldwide, including Xinjiang Yihua, Indonesia Xiangsheng, and Oriental Hope. Among them, the Indonesia Xiangsheng project set an industry record of 1,545 consecutive safe operation days, the Xinjiang Yihua project successfully solved the problem of high-alkali coal gasification, and the Indonesia Shengyin project verified the adaptability of high-water-content lignite. These projects not only demonstrate the universality of CGAS technology for various coal types but also win continuous customer trust with their "long-cycle, high-stability, and low-energy-consumption" performance, forming a virtuous cycle of "technological breakthrough - project implementation - reputation spread".

In the future, the company will continue to deepen the iterative R&D of CGAS circulating fluidized bed coal gasification technology, enabling technical advantages to be more directly translated into customer benefits and allowing coal clean utilization technology to release greater value. Choosing ZHGAS means choosing the dual guarantee of "strong research capabilities + excellent engineering implementation".